| - Performance

-

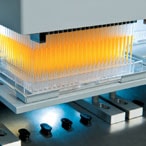

With its choice of different liquid handling arms as 2- to 16-channel liquid handling arms and MultiChannel Arm™ 96 and MultiChannel Arm™ 384Freedom EVO can be tailored to your performance requirements.

Liquid volumes range from 100 nl to 5ml and can be extended withDynamicFill™ Technology to 50 ml and higher.

|

| - Reliability and Precision

-

The Freedom EVO liquid handling arms combine reliability with advanced pipetting precision suitable for high density formats like 1536 well plates. The liquid level of samples can be detected and monitored during pipetting using capacitive and/or pressure methods.

With the safety option Pressure Monitored Pipetting (PMP™) errors are detected by comparing recorded and real-time-simulated pipetting pressure signals.

|

| - Flexibility

-

The liquid handling arm can be equipped with disposable tips and/ or washable tips with various chemically resistant and biologically appropriate coatings and lengths.

Get the highest degree of flexibility with the MultiChannel Arm™ 384 which works with 8, 12, 16, 24, 96 or 384 channels depending on your application needs.

|

| - Modularity

-

A choice among over 90 different arm configurations and possible reconfigurations of the modular instrument on site (e.g. exchange of arms) ensures that each system can evolve as your application requirements change.

Enhance the functionality of the platform with a variety of options and with an extensive range of carriers for positioning labware (e.g. tubes, plates, reagent bottles or slides) on the worktable.

|

| - Parallel processing

-

We offer liquid handling and robotic elements that work together to best automate your process and optimize your workflow.

Scheduling liquid handling simultaneously with plate logistics and management of other downstream processing steps increases process speed, enhances throughput and provides efficient use of all process resources.

|

| - PosID™ Positive Identification System identifies carriers and labware prior to and during the process to ensure integrity of samples, reagents and assays vessels.

The PosID robotic scanner is mounted at the rear of the worktable on Freedom EVO 100, 150 or 200 workstations. It has free range to monitor labware carrier positions and to automatically identify the codes of numerous labware types.

|

| - Te-VacS™ is an automated solution for vacuum solid phase extraction. The system can be assembled by the robotic manipulator arm for fully automated operations and is ideally suited for DNA /RNA extraction, viral RNA isolation or compound purification.

The module provides two separate vacuum positions connected to an high performance vacuum pump with separate vent lines for each vacuum position to prevent aerosol-caused cross-contamination.

|

| - Te-MagS™ is a powerful magnetic-bead-based sepa-ration tool for sample purification. Typical applications include DNA/RNA or protein purification as well as cell isolation.

The module can cope with 96 well formats as well as with 48 single test tubes. Automated magnetic mixing and an heating option ensure full process automation even on the smallest Tecan instruments.

|

| - Te-Shake™ is an highly effective shaker that can accommodate almost any type of microplates, deep-well plates, PCR plates or Eppendorf tubes.

The module is available in various configurations to address specific requirements like, for example, heated mixing and/or multiple parallel microplate shaking. Optional on-deck mounting allows pipetting actions during or between shaking periods.

|

| - The Monitored Incubator Option (MIO™) series is suitable for the incubation of standard microplates, including lids and half-height plates such as cell permeability plates including inserts and lids.

The incubator is available in six- or four-slot capacity modules with or without microplate shaking. Several incubator modules may be combined together to provide different temperatures and environmental conditions.

|

| - Using its Te-PS™ Tecan Positioning System Freedom EVO can reproducibly and reliably access high density format also with disposable tips and will even correct in real time possible tip misalignment.

|

| - Carousel LPT 280 EVO™ increases your walk-away time and raises your throughput.

The Carousel allows random access up to 220 standard microplates with an average access time of just 11 seconds per plate. It can handle stacks with various shelves spacing to allow storing a different type of labware or disposable tips in each stack and provides a Freedom EVO workstation with a medium storage capacity.

|

| - Te-Stack™ is an efficient tool for automating the storage, retrieval and fast delivery of microplates and disposable tips.

Each module holds up to 50 standard microplates, up to 15 deep-well plates or up to 12 tip boxes. More than one Te-Stack can be used for even greater processing speed and capacity.

|

| - Tecan’s Microplate washers and readers can be seamlessly integrated in the Freedom EVO liquid handling systems offering full automation of your application including washing and reading steps.

|